-

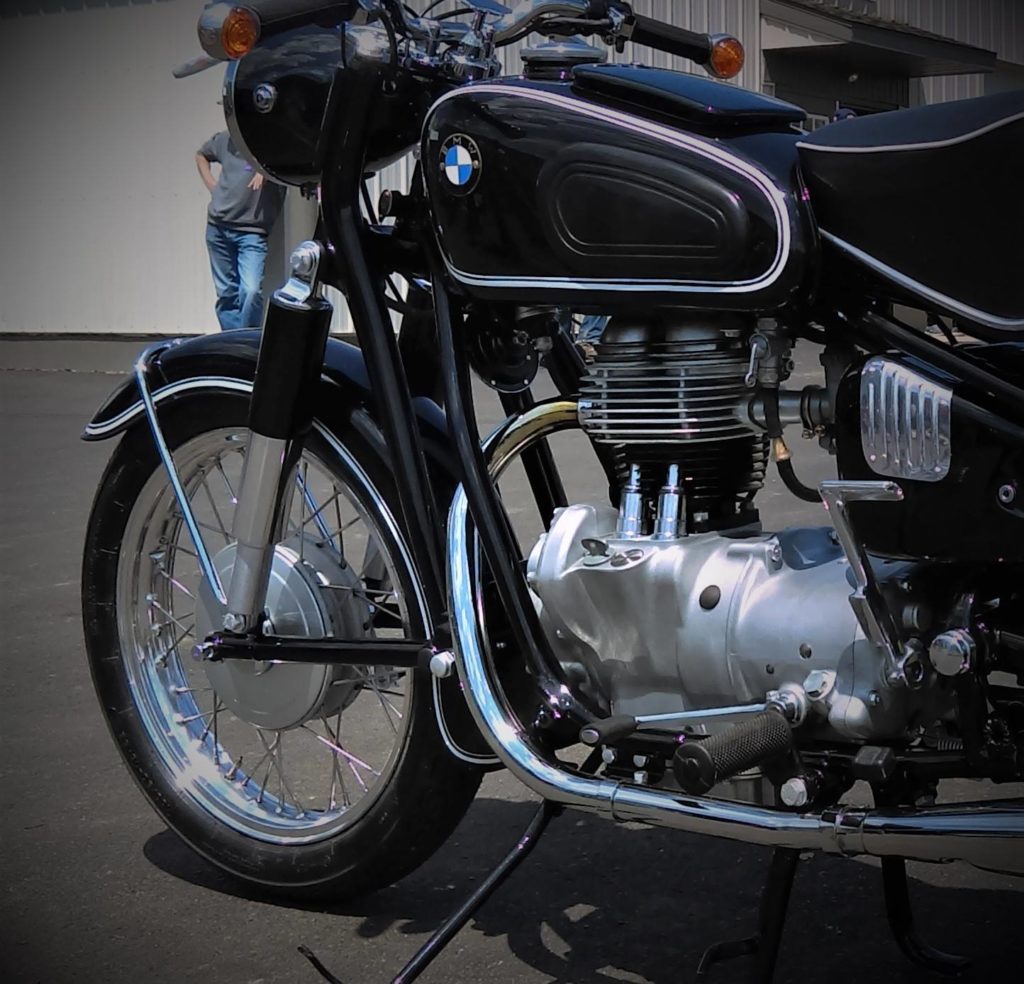

Frame: The Frame Man in CA

Crankshaft rebuild: Dan from Cycleworks

Paintwork: George from Autobody Specialties, Hauppauge, NY.

Powder coating: On-point Powder Coating, Oyster Bay, NY.

Pin Striping: Figgie

Parts and help: BenchMark Works, Vech and Richard.

Chrome and Cad: Rick from V-Twins, Oyster Bay, NY.

Cad plating: International Chrome Plating, Providence, RI.

Support: My Wife

Encouragement: Kurt

When I was a young boy a neighbor had a BMW motorcycle and I used to watch him go back and forth every day on it. It was a R60/2 (if I remember correctly) and back then it was a current motorcycle, not vintage. I always wanted one and when I was able to afford it both money and time wise I decided to buy one.

I came across and ad in Hemings Motor News for an R50/2 in “perfect shape” and decided to call. This is how I met Kurt! Kurt had placed the ad for a friend and was brokering the sale of several motorcycles for him. We made a date for me to see the R50/2 and after looking at it I decided to purchase it. Kurt and I became immediate friends and I kept in touch with him regularly.

I had caught the vintage motorcycle bug, big time!

Kurt was an older gentleman that was in Germany after WWII and would tell me stories of his BMW motorcycles that he used to tour the Bavarian countryside. His tales and his knowledge were both wonderful and it was great fun to speak with him. After the R50/2 was up and running (which did not take long because it was very low mileage) I began to look for a single cylinder BMW to do a more complete restoration on. Something I could spend some time on, learn and enjoy. I could tell Kurt had something in mind, but was reluctant to let me know.

After several phone calls, Kurt told me he had a R27 in his basement that “was really nice” and that he would be willing to sell it. It was a 1963, the motor was “broken” but the paint work was “very nice”. We made a date for me to go down and see the little R27.

When I arrived at Kurts house he had already extracted the R27 from his very full basement and had it outside. When I walked up he said “it’s not as nice as I remembered it”, and I agreed. The motor was in a hundred pieces, there were boxes of parts, the bodywork was scratched and dented. The amount of oil, mud, scratches and dents was overwhelming. With only 8,566 miles on the odometer I wondered why they would beat this little R27 so badly! It had the original tires, never had a tire iron touched the badly bent aluminum rims. All the original hardware and parts looked to be in place. They did nothing to it except for beat the living heck out of the poor thing! Kurt told me a wealthy family in Maryland had purchased the bike for their kids to ride. The motor broke and it was sold off as was.

After looking at the R27 I was unsure if I wanted to get into a restoration that deep and the amount of money Kurt was asking wasn’t commiserate with the amount of work needed. The depth of the restoration would be difficult with my full time job. I told Kurt it was too much for me to take on and declined the purchase. Kurt quickly tossed a number out to me that I just could not say “no” to and I decided to purchase the little R27. Little did I know how much I would need to do!

I seriously considered parting the bike out at first, but that is not what I bought it for and I had already fell in love with the little thumper.

The first thing I did was to verify that the odometer was correct, so I spun the cable in the housing until another mile ticked on the clock. The odometer worked just fine, but the trip counter did not. The mileage was correct!

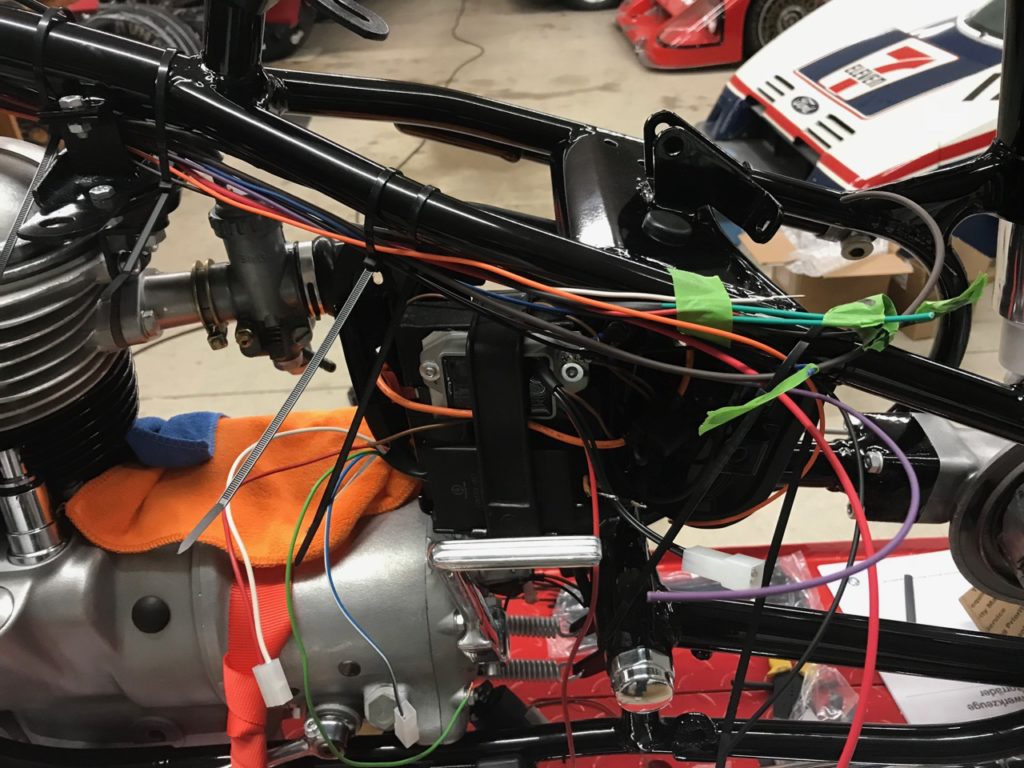

I began the process of taking everything apart and making sure I labeled where it came from. Every nut and bolt was labeled and bagged. I took countless pictures of everything during disassembly. Absolutely nothing had been done to the motorcycle, the original plug was in the head, the original wire, cap, etc was all there. The motor had been removed and the crank taken out because the rod was bent at almost a 90 degree angle.

First, the crank was sent to Dan at Cycleworks and he had told me he had R27 rods in stock. I asked him to install the slinger and bearings so when it came back it was ready to put into the block. I also had him do the camshaft bearings. Dan had told me that he was in the middle of many things in his life and that it may take some time to get my parts back.

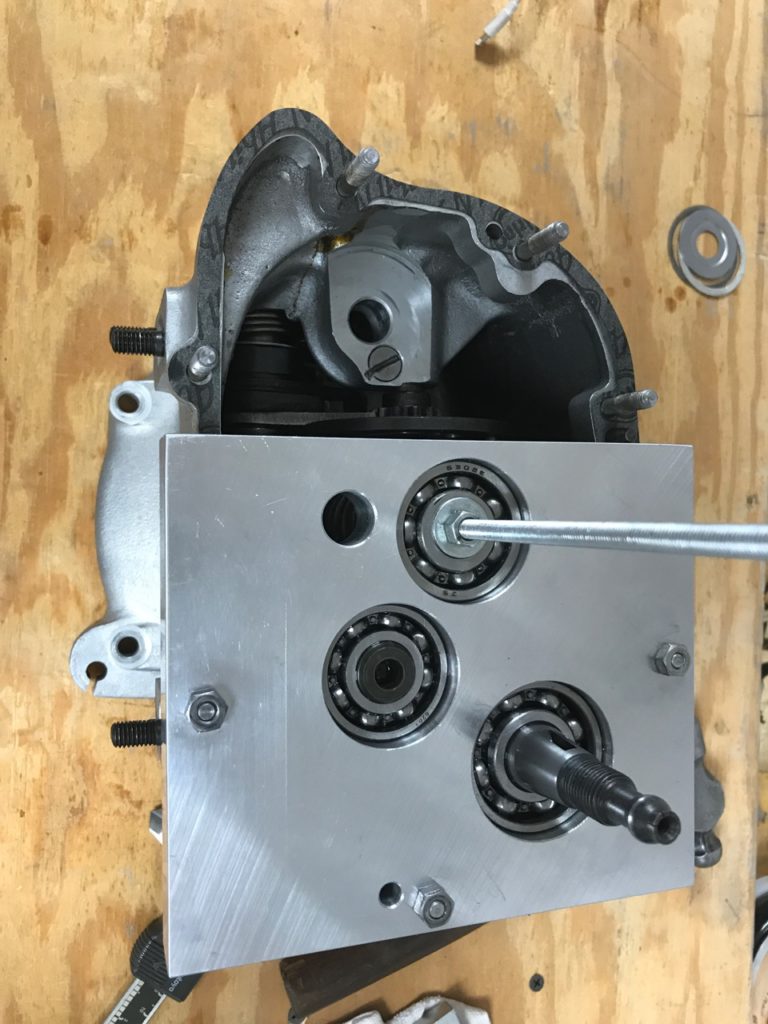

I then evaluated the gearbox and final drive. When I turned the final drive it was obvious that the ring and pinion was broken and when I pulled it apart large pieces of metal came out. I called Vech at Benchmark and he told me there was no way he could rebuild the final drive and that I would need to find one online! What made it harder was that I had the “middle” ratio, not solo and not sidecar but in-between. I got on ibmwr.org and shockingly found one in days. I sent it to Vech for rebuild (the rear was the only thing I did not want to do) and had it in my basement 2 weeks later done and ready to go!

The gearbox seemed fine but because everything else was so bad I figured I would disassemble that fully as well. I pulled the gearbox apart and shockingly enough it looked really good inside. Even though it looked good I changed the bronze bushings and put new shift forks in as the forks had wear on the ears. The gearbox was very straightforward to build.

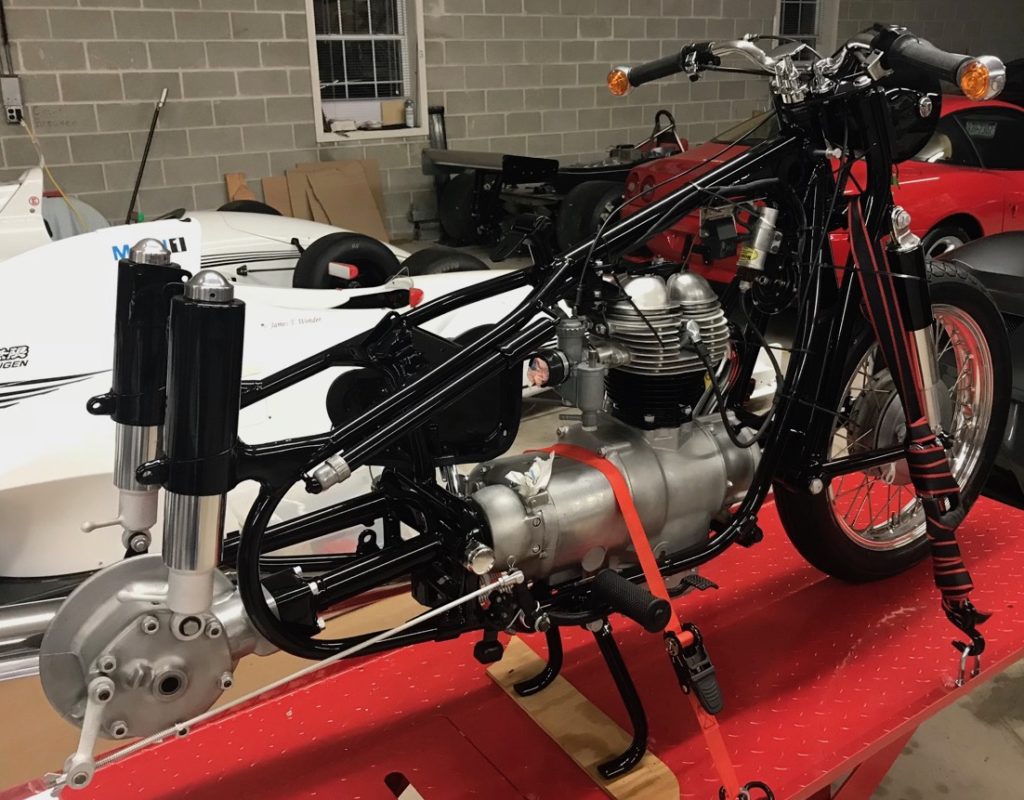

While I was waiting for my crank I cleaned and checked the frame to find that the frame and the Earls forks were both bent. I sent all the parts to “The Frame Man” in CA for repair and they had it all back in under 2 months.

During this time my crank came back from Dan and on a lark I measured the length of the connecting rod and he had put an R26 rod on it instead of an R27 rod. An honest mistake and I know he was distracted by other things. I sent it back to him to have the right rod put on it.

My frame came back and I gathered all the parts for powder coating. My local powder coater does a GREAT job and does not lay the powder on too thick. I also brought the bodywork to him to be chemically stripped and cleaned.

I sent the cylinder (which I purchased in Vermont) out to Boretech for evaluation and to have the carbon bore process applied. They suggested one size over so I ordered the piston from Vech and drop-shipped it to them so they could correctly size the bore and I also had the piston ceramic coated on the skirt!

I sent the head off to Memphis Motorworks to have it done over with new valves, seats, springs, etc etc. They also pressure checked the valves and springs before they sent it back.

I decided to use the wheels I purchased from Vermont because they did not have huge dents in them and were ready to mount on the motorcycle. All they needed was some cleaning and polishing. I also refinished the brake drums which came out nice and square.

At this point I had a gearbox, final drive, head, cylinder with piston, wheels, painted frame and bare bodywork that was sent to George the painter.

I finally got the crank back from Dan and was able to complete the build of the “short block” quickly. I timed the camshaft and got the ignition installed.